Our Products

Our extensive experience, knowledge and technical expertise is constantly being incorporated into our showcase designs.

Evolution

Full Flexibility: A Case for Change

Evolution is our flagship modular range. Introduced in 2003, Evolution-1 made an immediate and profound impact on the temporary and touring exhibition scene. Following a decade of success with this ground-breaking sustainable showcase solution, the Evolution-2 launched in 2013 and is now our default system.

The TESS Evolution system comprises individual case modules; these can be used as singular, stand-alone showcases or joined together to create larger and/or different shaped cases with no internal divisions. These modules can be quickly and easily fixed together to create larger showcases whilst maintaining the security and sealing that is expected of a permanent installation.

Modules can be assembled in an almost endless variety of custom configurations; available in two standard plan sizes of 700sq and 900sq, modules of the same size are required to join them together.

The TESS Evolution system comprises individual case modules, each of which can be quickly and easily fixed together to create larger showcases whilst maintaining the security and sealing that is expected from a permanent showcase installation. Modules can be assembled in an almost endless variety of custom configurations.

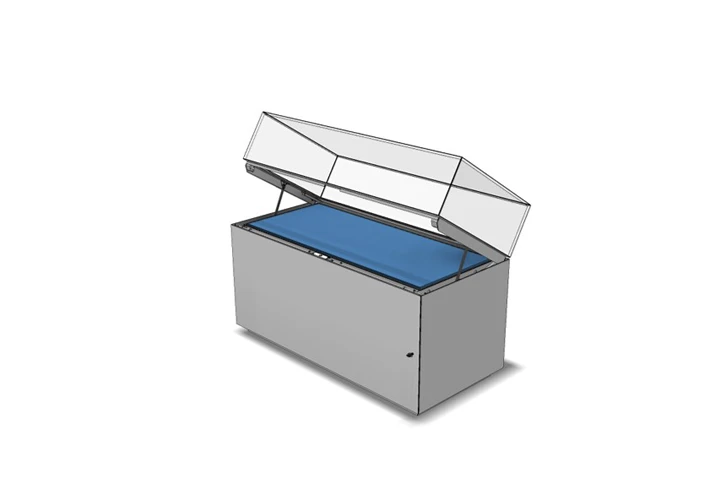

Prism

Viewing Versatility: The All-Rounder

Our Prism cases are the perfect choice for the display of smaller objects, books, manuscripts and documents. These museum display cases combine easy access with excellent visibility without compromising their high level of security and environmental control.

Prism is available glazed all around for use in the middle of a gallery when all-round vision is required, or with a solid back when the cases are to be positioned against a wall or back-to-back. A variety of standard sizes are available, although we can of course custom-create them to suit your specific needs.

Various plinth options are available, and these showcases are easily separable from their supporting plinths for ease of movement or transportation.

TESS Evolutions really are the cases that do it all. Full spec conservation performance, high security, demountable and truly modular.

Hirohide Onishi

Design Engineer